Mechanical Design

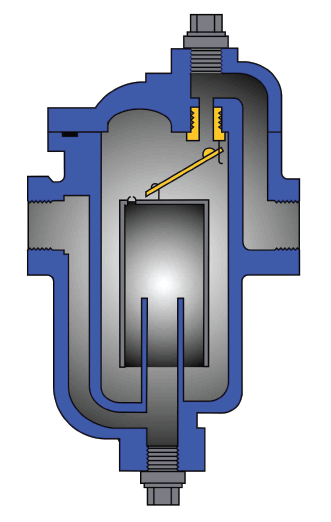

Inverted Bucket Design

The inverted bucket design operates on the principal of the difference in density between steam and water. During normal operation the steam inside the bucket is continually lost through the air vent in the top the bucket and discharged throught the lever valve. Testing shows the steam loss through the air vent hole to be approximately 3 pounds of steam per hour.

Applications:

Pressure Ranges

0-1500 psig

Size Ranges

1/2"

3/4"

1"

1 1/2"

2"

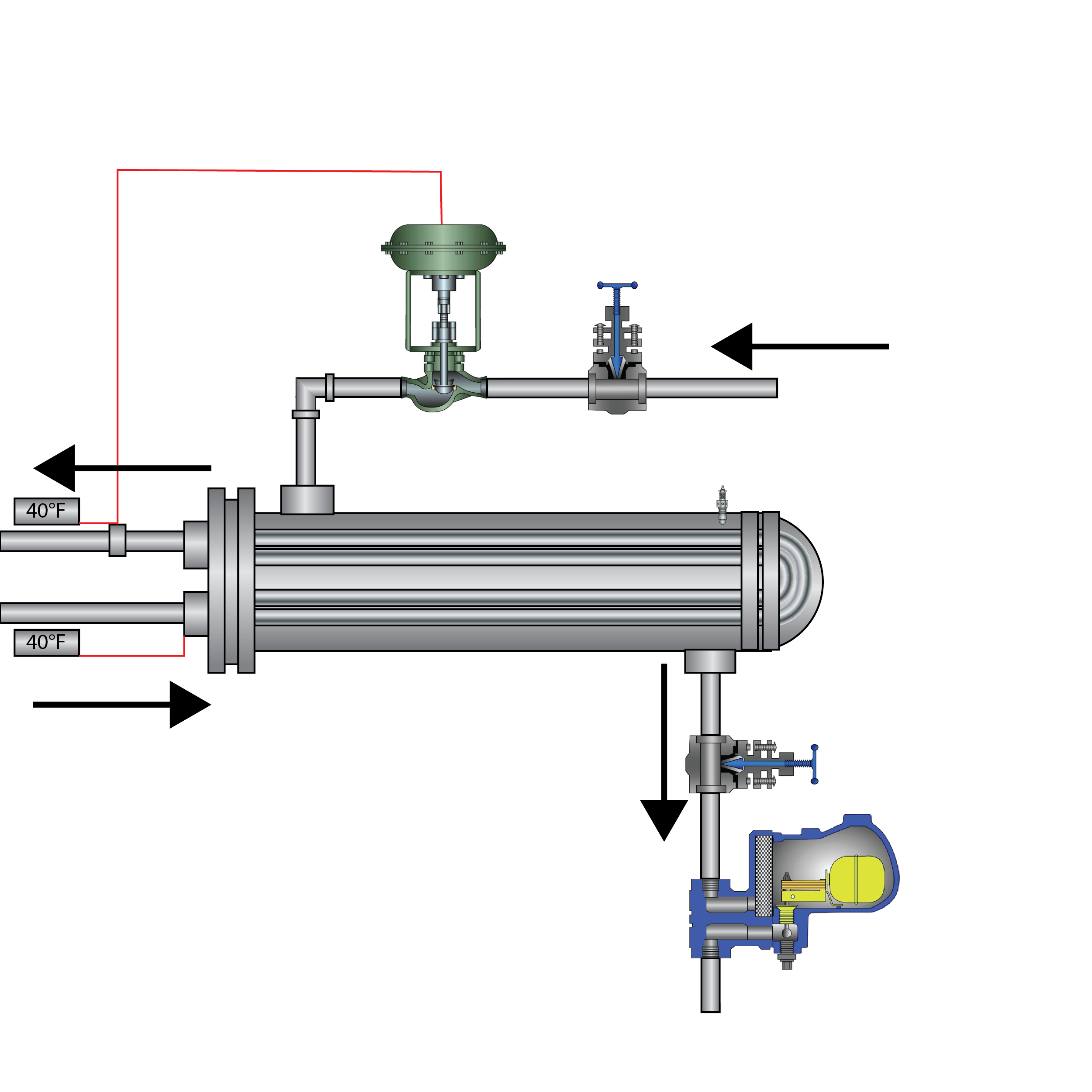

Float and Thermostatic

The float and thermostatic design operates on both density and temperature principals with 2 orifices in the body of the trap. This design provides for air-venting through a secondary orifice controlled by a thermostatic bellows. It discharges condensate through a main orifice controlled by a hinged float assembly. This design will fail in the closed position

Applications:

Pressure Ranges

0-600 psig

Size Ranges

1/2"

3/4"

1"

1 1/2"

2"

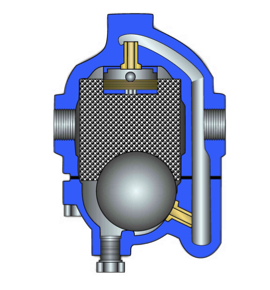

Ball Float

The ball float design operates on both density and temperature principals with 2 orifices in the body of the trap. This design provides for air-venting through a secondary orifice controlled by a thermostatic bellows. It discharges condensate through a main orifice controlled by a ball float. This design will fail in the closed position.

Applications:

Pressure Ranges

0-600 psig

Size Ranges

1/2"

3/4"

1"

1 1/2"

2"